Our office hours:Mo - Fr | 07.30 - 16.00Call us:+49 911 659 680

Parapet Anchor

Concrete Screw

TOGE TSM Parapet Anchor

Fastening of scaffolding and formwork in the renovation area

Our TOGE TSM parapet anchor: In combination with injection mortar, it allows high load bearing in cracked and non-cracked concrete. Approved for concrete strength classes from C20/25 to C50/60, it is suitable for fixing concrete formwork in refurbishment applications. During processing, the composite mortar seals the drill hole and thus prevents water penetration.

TOGE TSM Parapet Anchor – At a Glance

Fast and safe installation

The optimized thread enables a quick and easy embedment process.

High Loads

High load bearing capacity in cracked and non-cracked concrete.

Frostproof

Sealing the borehole prevents water penetration and frost damage in winter.

Immediate Load

Immediately loadable directly after installation.

Sustainable

Reusability of the fastening part.

Headshapes and Materials

Which product is right for you?

Do you need support?

We will be happy to help!

Call us: +49 911 659 68-10

Application Examples

Fixing scaffolding and formwork in the renovation area

Approval | Installation Instructions | Technical Information

Approval

Base Material

Application in cracked and non-cracked concrete

of strength classes from C20/25 to C50/60.

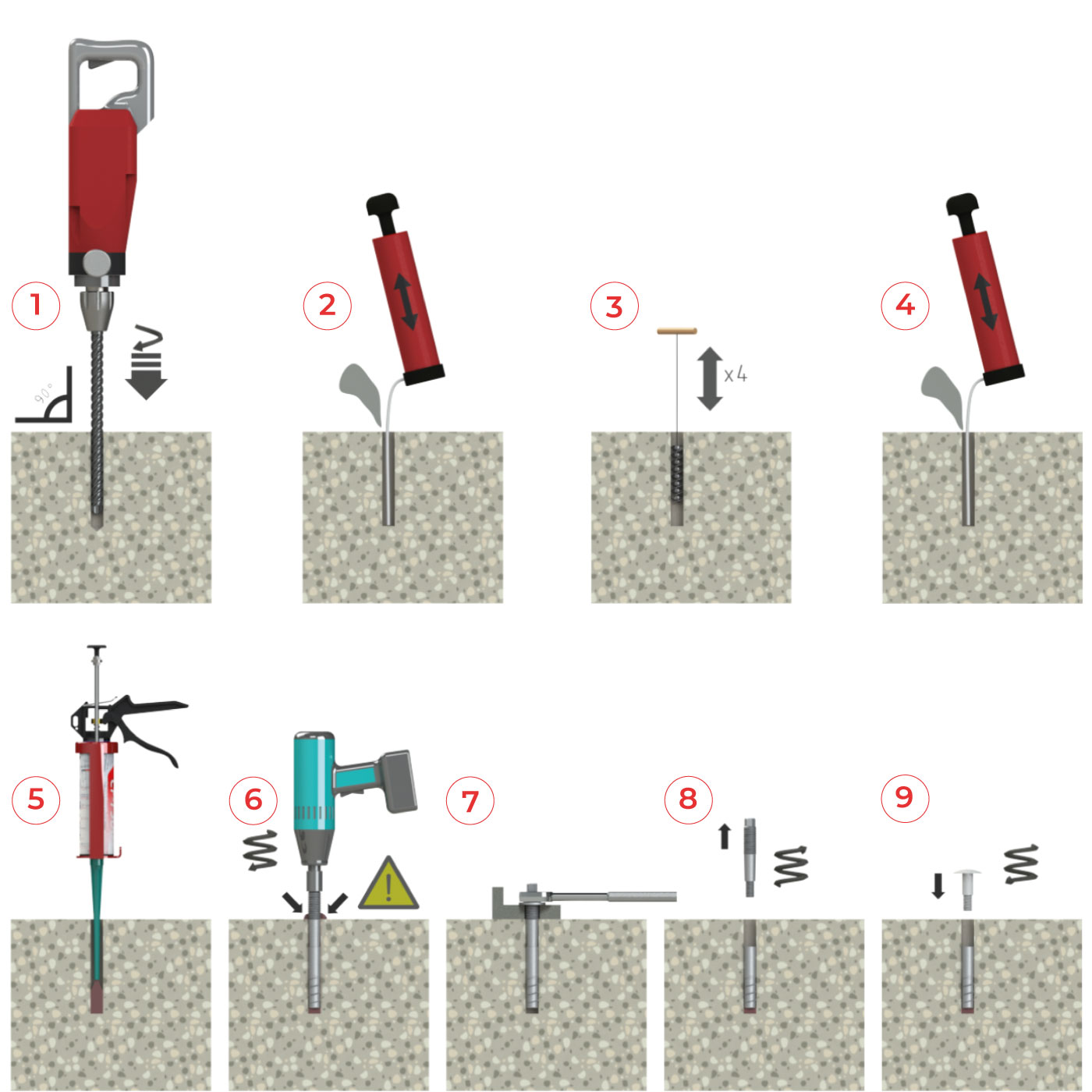

This is how simple the installation works:

- Drill a hole perpendicular to the concrete surface.

- Thoroughly blow out the borehole.

- Brush the borehole 4x.

- Thoroughly clean the borehole again.

- Inject composite mortar.

- Screw in screws with an impact screwdriver. After reaching the screw-in depth, the composite mortar must emerge at the concrete surface.

- Fix the attachment.

- After work, the screw-in aid can be easily unscrewed.

- Seal the hole left behind with the screw cap.